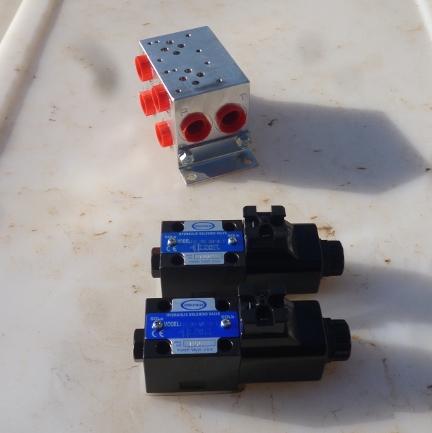

Solenoid Valves

September 20, 2012 The microprocessor that lies at the heart of the Biomass Compressor controls the process by means of a bank of electronically operated hydraulic valves, one for each stage of the compressor. That's straight-forward enough, but the catalogs offer what is to this novice's eyes a confusing array of valve types. The type of valves needed are expensive, so the task of figuring out which specific valve to purchase is daunting. At a hundred dollars each, I wanted to get the right valve the first time. The task of valve selection is made even more complicated by the need to also purchase a manifold upon which to mount the valves. The purpose of the manifold is to by-pass the need to route pressurized hydraulic fluid to each valve, thereby eliminating a rat's nest of hosing and tee-fittings. Feeling woefully incompetent to sort through the variable for just the right valve and manifold set up, I went in search of someone who had the needed competency. I'm delighted to report that I was able to make contact with Steve Hummel and the good folks at Motion & Flow Control Products, Inc. in Portland, OR. Steve took the time to understand the application we're working on, and then walked us through the confusing range of options involved in selecting a set of 24 VDC solenoid operated high-pressure hydraulic valves along with the manifold they mounted on.

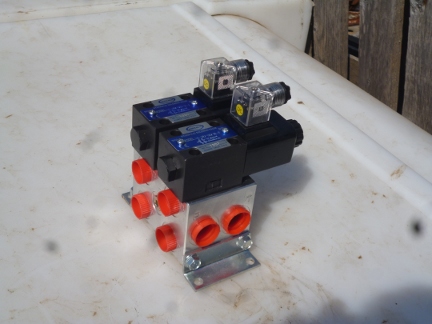

Mounting the valves on the manifold couldn't have been easier. Each valve has an orientation pin that ensures that it can only be installed in one orientation. The bottom of the valve has o-rings that make the seal without having to use a gasket or any sort of sealing compound.

The round red things are plastic plugs that will be replaced with hose fittings at time of installation. For now, they ensure that the interior of the valve pack stays clean. |