What is the GEK?The development of the Gasifier's Experimenter's Kit, known affectionately as "the GEK", has enabled significant advances in the small-scale conversion of woody biomass, everything from wood chips to walnut shells, into combustible gases of sufficient purity that they can be use to reliably power modern internal-combustion engines.

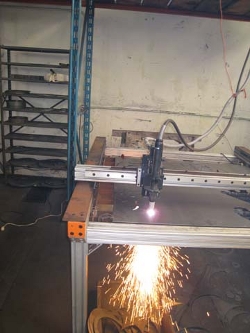

Because of the incredible variety of configurations that the use of obtainium resulted in, it was very difficult to use those small, one-of-a-kind gasification systems to discerne the fundamental principles involved. That understanding is needed in order to answer key questions such as, "Why does one system perform better than another?" Mason's vision involved putting together a series of CAD drawings that can be used to generate a standardized gasifier using a computer-controled plasma cutter. He then offered free access to the CAD files so that anyone with access to a plasma cutter and sheet steel could create their own GEK. For those without access to high-tech cutting gear, Mason offered ready made sets of computer-cut components so that anyone with basic welding skills could put a GEK together. Mason's vision made sense to us, and Opalyn and Walt made the trek down to All Power Labs in June of 2008 to weld up and bring home GEK #004.

For more about Opalyn's experience, Click Here. A year later we returned to upgrade our initial unit and utilize the substantial improvements that Mason's open source concept had engendered in just that short amount of time. The newly updated unit, now known as GEK #170, was immediately put to use providing fuel gas for a single-cylinder Lister, an engine designed to run on diesel, but which was in the process of being converted to operate solely on wood gas. That's Opalyn in the brown welding jacket at 0:10 into the video using GEK #170 (formerly #004) to provide fuel gas for the Lister. That was so much fun that after our return to Windward, we couldn't resist checking out how our diesel tractor would react to a taste of wood gas. A diesel engine won't run on pure wood gas but wood gas can supply up to 80% of a diesel engine's needs. That's easier to do with a stationary diesel engine and tractors are mobile, but actually a lot of the work we ask "Big Blue" to do involves stationary chores such as chipping wood. It will be sweet to have a trailer-mounted GEK that can help fuel our wood chipper's power source with a small fraction of the wood chips it's producing.

|