Biomass Control Computer

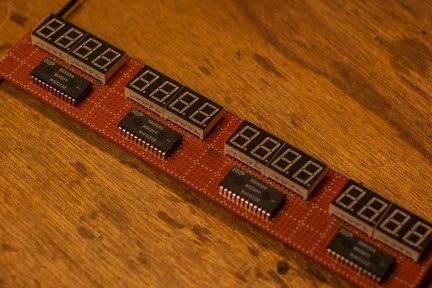

January 11, 2014 The Biomass Control Computer (BCC) is the electronic brain of the Biomass Compressor: a multi-stage hydraulic gas compressor. Unlike home computers, which mainly deal with media and information, a control computer interacts with the physical environment. In our case the BCC carefully observes the pressure in the different tiers of the Biomass Compressor, reacts to the changing position of the pistons, and opens and closes solenoid valves at just the right time. The computer also displays sensor data on digital gauges and gives the operator the capacity to manually intervene, or change program parameters between compression cycles. I've built computers all my life, but this project excites me because I get to go far beyond researching the appropriate components for the task and assembling them according to established industry form factors. I look forward to designing everything from the power supply to the user interface, to create a replicable on-of-a-kind machine. With that said, this device is more to me than just a tool, it is a testament to my passion for technology and my commitment to the B2M project. The BCC is being developed in the spirit of Open Source: I hope to publish the code I produce as well as technical drawings, circuit diagrams, and parts lists. I also plan to make good use of available Open Source resources to expedite the development process. TechnologyThe working specifications are as follows:

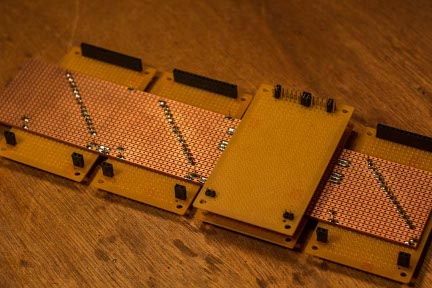

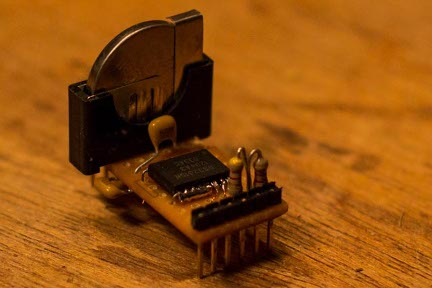

DevelopmentIt could be said that a computer is a collection of subsystems that work together to produce the desired computational functionality. With that in mind, the development of the BCC too can be understood as a collection of smaller projects coming together in unison.Early on I identified some of the core subsystems for the BCC:

To view the circuit schematic, Click Here. To view a short video of the demo setup in operation: Click Here. The development of the first, actual BCC is a work in progress: it includes scaling up the already established subsystems, but also many additional tasks like manufacturing the enclosure, the front panel interface, and making wire harnesses for power, for sensors and solenoids. As the work on this project continues there will be more pictures, diagrams, and videos. For now, here are some pictures of components I've been working on recently:

|